Protein Precipitation/ Peptide Purification

Solid Phase Extraction (SPE) is commonly used for mass spectrometry sample preparation, but traditional syringe cartridges (1ml, 3ml, 6ml) struggle with small-volume samples, leading to poor recovery and inefficiency. This is a challenge in metabolomics and peptide research, where high-throughput processing of small human samples is required.

SPE filtration plates have been developed for low-volume extractions (less than 1ml) and have the exact layout/dimension as a standard 96-well plate which supports a high-throughput (96 samples at a time) but low-volume (less than 1ml) extraction. Using positive pressure or a vacuum manifold, these plates push eluents through the filter and the whole workflow looks almost identical to the ones using ordinary carbon cartridges.

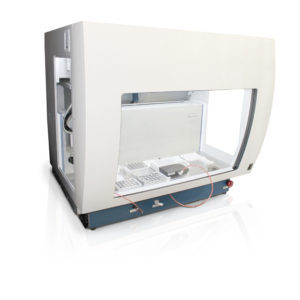

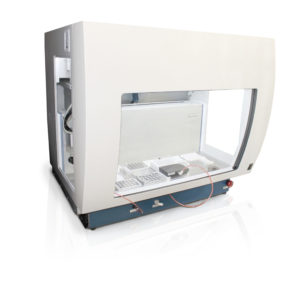

One of our hospital core lab clients uses Phenomenex’s Impact™ Protein Precipitation Plates with the VERSA 1100 SPE Workstation for GC/MS analysis. The VERSA 1100 SPE accommodates 1ml, 3ml, 6ml cartridges, and 96-well SPE cartridge plate formats. With 15 deck positions and versatile modules—positive and negative pressure applicators, nitrogen dryer, and shaker-heater—this system automates extraction, derivatization, and reconstitution for faster, more reproducible results.

Thermo’s SOLAµ™ SPE Plate

Phenomenex’s Impact™ Protein Precipitation Plates

Applications – VERSA Automated Solid Phase Extraction Systems

- Food Safety

- Vitamin D from Blood/Serum Samples

- Drugs of Abuse in Forensic Analysis

- Environment Health

- Compounds for Drug Discovery

- Iso-flavonoids from Urine Samples

- Aflatoxins from Seafood Products

- Metabolite Extraction

- Growth Promoters in Blood

- Semi-volatile or Non-volatile Analytes

- Protein Precipitation

Specifications | Versa1100 | Versa2100 |

| Deck Capacity | 15 | 24 Deck Positions |

| Pipetting Head (Single Channel Function, Disposable Tip) | 4 or 8-channel | 4 Channel Pipette (1000uL) |

| ReagentDrop | up to 8 | 5 Channel Reagent Drop (bulk dispensing) |

| Supported Cartridges | 24 test tubes/vials and 96 deep well plates | SPE cartridge compatible |

| Gripper / Plate Transporter | Gripper | Gripper |

| Reagent Block / Flat Plate Coolers | Optional | Optional |

| Nitrogen Dryer | 24 or 96 channels | 24 or 96 channels |

| Shaker-Heater (2400rpm, RT to 90°C) | Optional | Optional / 4-in-1 Shaker for 4x Sample Tube Racks 4×6 |

| Liquid Level Sensing | Optional | NA |

| HEPA/UV/LED Enclosure | Included | Included |

| Sonicated Wash Station | NA | Optional |

| Width x Depth x Height (cm) | 99 x 75 x 90 | 120 x 84 x 200 (Including Bench) |

| Weight (kg) | 162 | ~500 |

What is the throughput?

It can be configured for 24-sample or 96-well format depending on instrument channels (4 or 8-channel head) – actual throughput time will depend on the specific procedure and steps involved.

Does the instrument come with its own nitrogen supply or does it use the lab’s?

The workstation’s nitrogen dryer has to be connected to the overall lab’s nitrogen supply for any drying step.

What liquids are compatible?

a. For ReagentDrop – most organic solvents are compatible – avoid concentrated aqueous solutions (salting out could clog the tubing) and concentrated acids or bases (can degrade metal components).

b. For pipetting and solutions on deck – avoid very volatile solvents and any concentrated acids or bases (fumes can degrade instrument components).

What is the sample handling volume?

a. Pipette maximum aspiration/dispensing volume is 1000uL.

b. Samples handling is around 10-15 mL.

Can the samples and solvent be kept cool?

Yes, we have cooler/heater flat plates that can bring down the temperature to 4 oC.

What sample sizes/consumables are compatible?

We have custom fabrication/3D printing abilities to meet whatever your needs.

What if my solvent is not compatible with polypropylene pipette tips?

We can offer a steel-pin system (4 or 8-channel, up to 1000 uL) system.

Is barcode tracking available?

Barcode tracking is optional.

What column sizes are compatible with the VERSA 1100 SPE?

Our system can fit 1 mL, 3 mL, and 6 mL SPE cartridges which would then use a positive pressure module, as well as 96-well SPE extraction plates which would use a vacuum system instead of a positive pressure modulator.

Difference between a vacuum system and positive pressure module?

A positive pressure module will be used for conditioning, washing and elution if the samples are processed in cartridge columns. A vacuum system is used if the samples are processed in a 96-well plate.