Consumers purchase decisions on products are often dictated by their chemical composition as awareness around the health hazards of toxic chemicals have shown to be linked to many health hazards. One example is Bisphenol A, BPA. Today many customers look for BPA-free water bottles, toys, and food packaging. What will be the next BPA? How can you improve your product so it doesn’t end up like a BPA water bottle?

Liquid-liquid extraction (LLE) is an analytical technique used to test products for extractable and leachable polymers.

Product safety testing utilizing LLE is a repetitive process which can be automated using robotics. Here is an overview of the current problem and solution.

Extracting Microplastics

Save the sea turtles!

Marine trash – mostly plastic (or micro-plastics), is a persisting problem that wreaks a havoc to ocean ecology, which then eventually will lead to a ‘backfire’ on ourselves.

Microplastic is an important environmental issue. Companies and consumers are taking action to reduce the amount of plastic that goes into the ocean. Some sources of plastic aren’t from plastic, but from polymer coating on common household products. These items contribute to the plastic in the ocean. How can you tell if your product is contributing to this problem? How can you test to inform consumers about your product?

Polymer Reporting for CGMP

Aside from tracing plastics in water samples, monitoring any chronical leakage of chemical substances from medical or day-to-day-use product also becomes critical more than ever: both USA and Europe have established certain regulations (in 21.CFR and EudraLex, respectively), to both pharmaceutical and manufacturing industries. The corresponding study is called “Extractables and Leachables Testing” (E&L Testing).

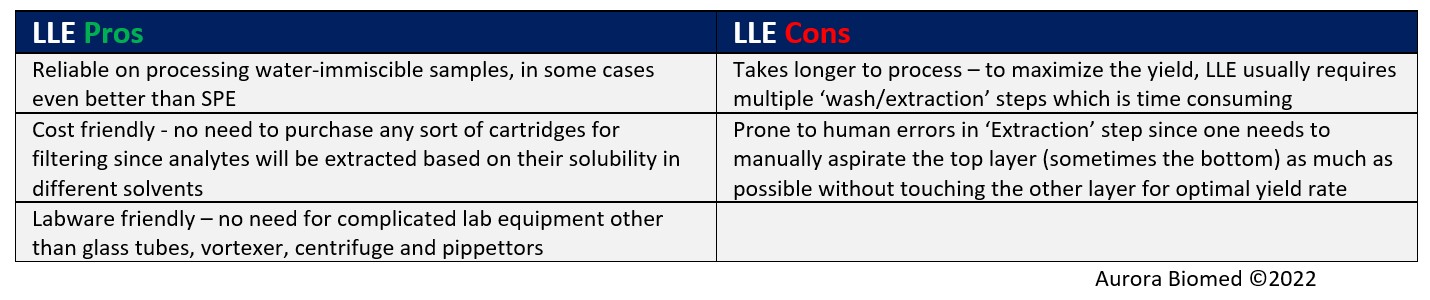

Pros and Cons of Liquid-Liquid Extraction

Liquid-Liquid Extraction (LLE) has been widely applied for sample preparation for extractable and leachable testing. Compared to Solid Phase Extraction (SPE), LLE is considered more ‘traditional’, however has limitation with processing water-immiscible samples. LLE also takes longer time to process. Even with these limitations it is continued to be used because it is reliable when working with aqueous samples, and does not require complicated labwares (pippettors, glass tubes, vortexer and a centrifuge may be sufficient already).

Manual LLE workflow can be time-consuming and constrained to a low throughput, let alone the contamination and low-recovery rate due to human errors.

Automation Solves the Problems of Manual LLE

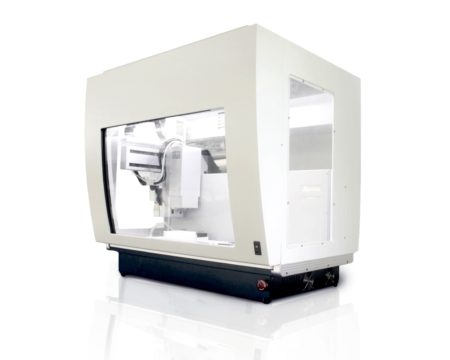

Automation solves all these problems of manually doing Liquid-Liquid Extraction. A robotic arm runs the LLE protocol. This reduces human errors. An automated system frees up time for staff to work on other things. For Jordi Labs, a fully automated LLE workstation saves the day. They are an analytical lab located in USA and are currently running Versa 1100 LLE to fully automate the workflow of detecting polymers like phenol, Methylundecanoate, BHT, and the Phthalate in their E&L Testing services.

Automated LLE workstation for Extractable and Leachable

VERSA 1100 LLE provides a complete walk-away solution which covers sample transfer among vials/tubes, vortexing and drying, buffer loading and layer extraction. With Liquid Level Sensing module, the instrument detects phase boundary and ensures precision, reproducibility, and minimal dead volume, and with built-in shaker/nitrogen dryer, the instrument is able to perform both vortexing and drying in one go, minimizing the usage of other equipment as well as off-deck proceeding time. Aside from various add-on options for hardware modules, our software is also highly flexible – client can request for implementing extra functions to facilitate their protocol. Contact us today to chat about your workflows and see how we may provide you an automating solution!