Technology seems to be the way of the future, and this is especially the case for laboratories in a variety of industries. Many laboratories have started reaping the many benefits of switching to automated liquid handling. In fact, so many laboratories are making the change that by 2024 the Global Automated Liquid Handling Market size is projected to reach $1.05 billion. This beginner’s guide to understanding automated liquid handling will help you understand the basics and benefits of this efficient and precise technology.

What it does

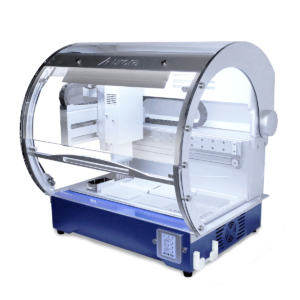

Automated liquid handling equipment can come in many different shapes and sizes for use in various fields. These machines use a motorized pipette or syringe, attached to a robotic arm, to dispense a specified volume of liquid or a sample to a designated container. Some models come equipped with additional laboratory devices and can perform additional operations, such as heater-cooler plates (link), to meet specific requirements. These modifications ensure that the liquid handling process is as thorough, efficient, and as precise as possible.

What can be automated

- Nucleic Acid Preparation

- PCR Setup

- Next Generation Sequencing, NGS Library Sample Preparation

- ELISA

- Solid Phase Extraction, SPE

- Liquid-Liquid Extraction, LLE

- Bio Array or Spot Printing Workstation (contact & non-contact)

- Liquid biopsy

- And more

Benefits

- Reduce human error

- Reduce human labor

- Reduce contamination

- Constant results running 24 hours 7 days a week

There are many benefits to automated liquid handling in a laboratory setting. First, because automated liquid handling utilizes high-end robotic technology, it greatly reduces the risk of human error. These machines provide extremely consistent and accurate results and the chance for error is significantly less than it would be with manual liquid handling. Additionally, this technology replaces the need for human lab technicians to perform the repetitive and sometimes mundane tasks manual liquid handling requires. Not only does this allow the lab technician to spend their time on other tasks, such as analysis of samples, but it is also more cost effective. Reducing the margin for error and freeing up lab technicians for other tasks will make the process much more efficient and economical.

Industries

From healthcare to academics, automated liquid handling can help increase efficiency and effectiveness in several different industries. In the agriculture industry, technicians can use liquid handling equipment to identify diseases and predict offspring of crops and livestock, helping avoid future loss or disease. Those in forensics also utilize automated liquid handling, aiding scientists in investigations by isolating high-quality genomic DNA from blood samples. There are several different applications for automated liquid handling in the field of forensics, as well as several applications in a variety of other industries. The use of liquid handling machines will vary across industries. As such, understanding automated liquid handling as it relates to your specific sector is imperative.

A robotic arm. Some arms have a griper to move plates, a pipette, and reagent dispenser.

The VERSA 10 a small automated liquid handler that has 6 customizable decks.

A gripper on the robotic arm, able to move plates.

Do you have a certain application in mind?

Interested in learning more about Aurora Biomed’s automated liquid handlers?

Fill out the contact form below to schedule a demo.